posted 1st August 2025

AECOM recently completed a scan-to-BIM project at a complex wastewater treatment facility using a hybrid workflow of traditional laser scanning (TLS), mobile mapping, and ClearEdge3D’s EdgeWise automated modeling software. This approach enabled significant modeling progress before on-site scanning was complete, cutting weeks from the timeline.

Project Overview

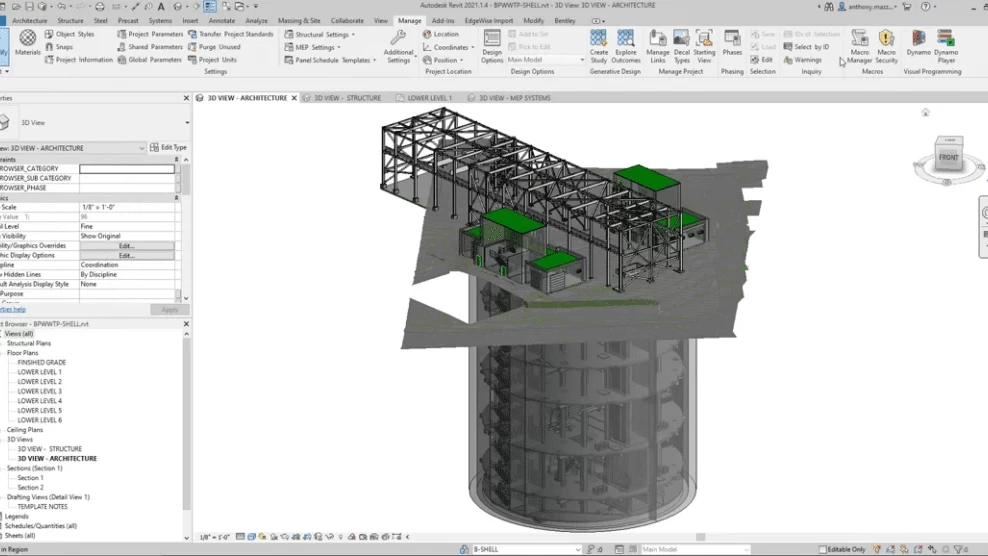

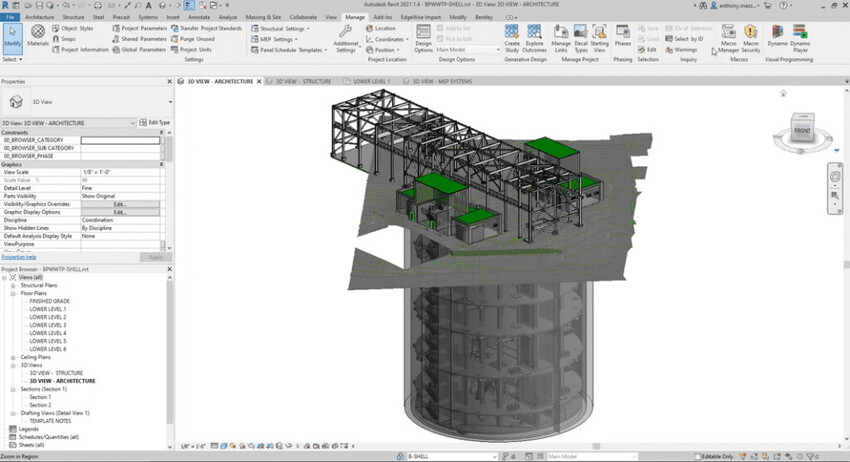

AECOM was tasked with capturing and modeling architectural and MEP elements at a large, multi-level wastewater facility located 150 feet underground in a dense urban area. The project required high accuracy (LOA 200) and fast delivery, making it an ideal opportunity for AECOM’s Digital Practice Innovation group to test advanced workflows.

The Challenge

The facility’s intricate layout and extensive MEP systems demanded precise alignment of data from SLAM-based mobile mapping and TLS technologies. The goal was to deliver a cohesive, high-quality model quickly, proving the value of digital tools in accelerating project timelines.

The Workflow

AECOM began by establishing a robust network of control points, starting outside and extending throughout the facility’s interior. Vertical control was placed in stairways to ensure proper alignment across levels.

Each level was scanned separately using the NavVis VLX mobile mapper. Control points were used to lock scans and reduce drift. Stairways were captured next, followed by TLS scanning for higher accuracy.

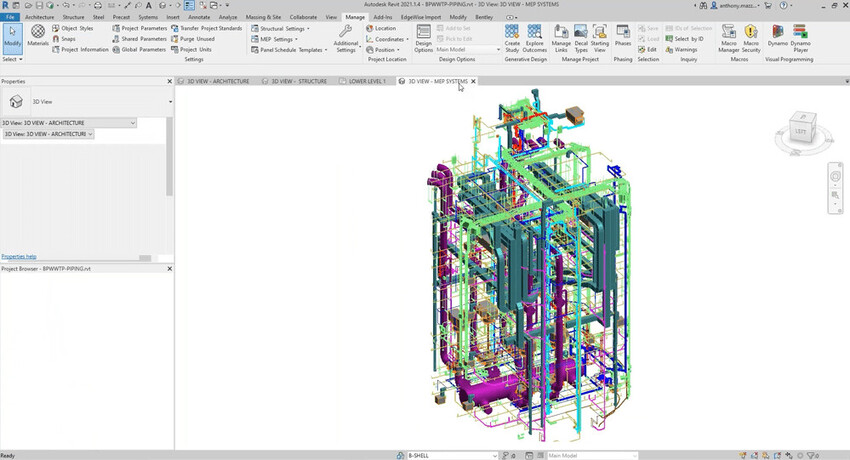

Meanwhile, the modeling team began building the Revit model using PDF plans, allowing early modeling of basic architectural elements. Once NavVis data was available, it was integrated into Revit to refine the model. EdgeWise was used to process the mobile mapping data, automatically modeling large MEP components and providing an early overview.

When TLS data arrived two weeks later, it was processed in EdgeWise to complete much of the remaining MEP modeling. Manual refinement followed, and the team conducted QA using IFC exports, clash detection, and point cloud comparisons.

Results

The hybrid workflow significantly accelerated delivery. NavVis scanning took just one day, enabling immediate modeling. EdgeWise automated about 40% of the piping and conduit modeling, achieving an RMSE of less than 0.08 inches—within a credit card’s thickness of real-world dimensions.

The entire project was completed in four weeks. A traditional TLS-only workflow would have taken seven weeks or more. The integration of mobile mapping, TLS, and automated modeling proved to be not only faster but also highly accurate.

Conclusion

AECOM’s approach demonstrated that combining mobile mapping, TLS, and automated modeling delivers both speed and quality. The dense, well-aligned point cloud produced by merging NavVis and TLS data ensured high fidelity in the final model. Critical elements like piping matched real-world conditions with near-perfect accuracy.

“When used in the right applications, these technologies give the best of both worlds—speed and quality,” said the team. “And it’s the important kind of speed—the speed of actually being able to do your work.”